1. Physical and chemical properties

Grade | Density (g/cm3) | Hardness (HRA) | TRS (N/mm2) | Application |

YG8 | 14.7 | 89.5 | 2000 | High stress, impact and shock resistance higher than YG6A, but wear resistance and cutting speed comparatively lower, roughing of cast irons, non-ferrors metal and their alloys as well as non metallic materials at low cutting speed. |

YG10X | 14.5 | 91 | 2400 | Fine grain alloy, good wear resistance. Used for processing hard wood, veneer board, PCB, PVC and metals. |

YG15 | 14 | 86.5 | 2500 | Conventional wear resistance, high bending strength, used for steel alloy etc. |

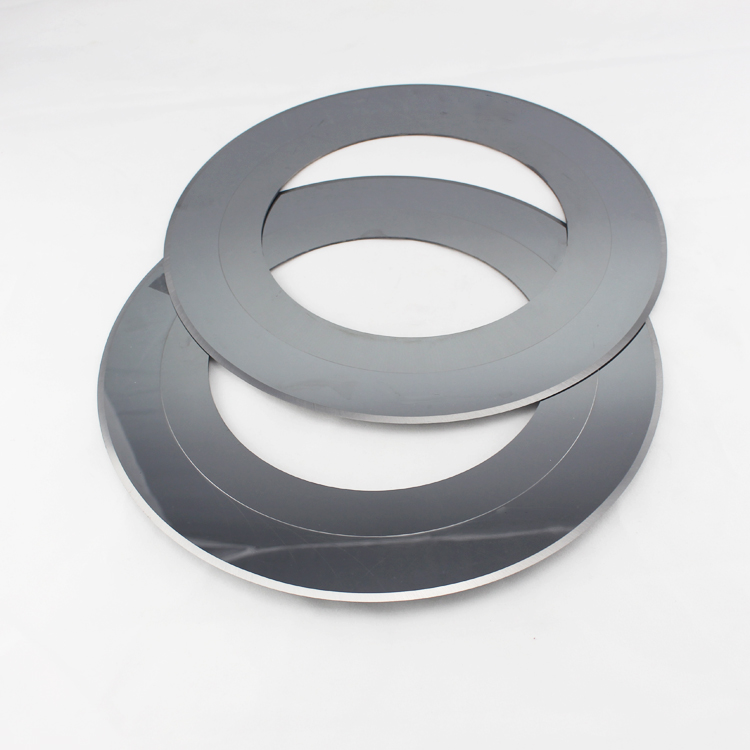

2. Product detail

Product name | tungsten carbide slitter knives |

Material | tungsten carbide |

Grade | YG10X, YG8, YG15 |

Part of Size/ Type (accpet customized size) | 250x105x1.5 |

260x105x1.5-6holes | |

230x130x1.5 | |

260x140x1.5 | |

260x142x1.5 | |

260x114x1.5-8holes | |

260x112x1.5-6holes | |

260x110x1.5 | |

260x158x1.5 | |

260x170x1.5 | |

200x122x1.5 | |

200x120x120 | |

210x122x1.5 | |

215x122x1.5 | |

220x110x1.5 | |

230x110x1.5 | |

230x135x1.2 | |

Packing | 2 pieces per foam box with cover |

MOQ | 5 pieces (sample is also available.) |

Delivery time | For the normal type which we have mould, it takes 7-30 days as per your quantity after receiving the advance payment. |

3. Application

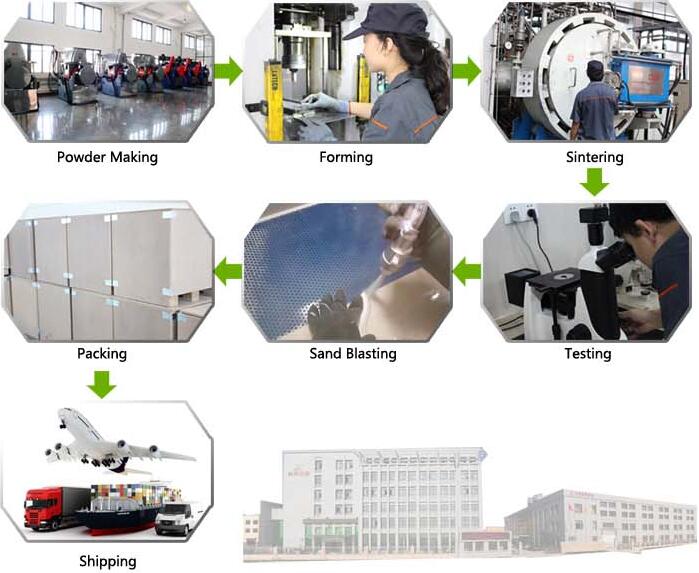

4. Production process

Last one:Tungsten Carbide Rollers